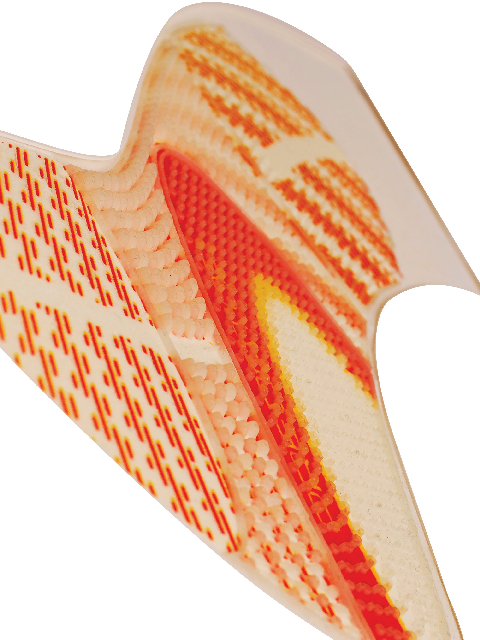

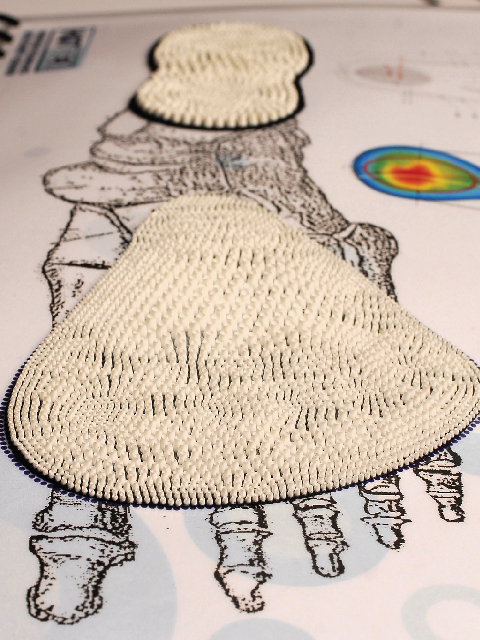

We have developed a cutting-edge coating process that utilises specialised polymers and specialised 3D surfaces to enhance the structure of fabrics in specific areas. Through our pressure-sensitive mapping (PSM) process, we apply these advanced polymers onto the insert panels of high-tech garments to improve contact areas, ultimately enhancing power and performance (CPP).

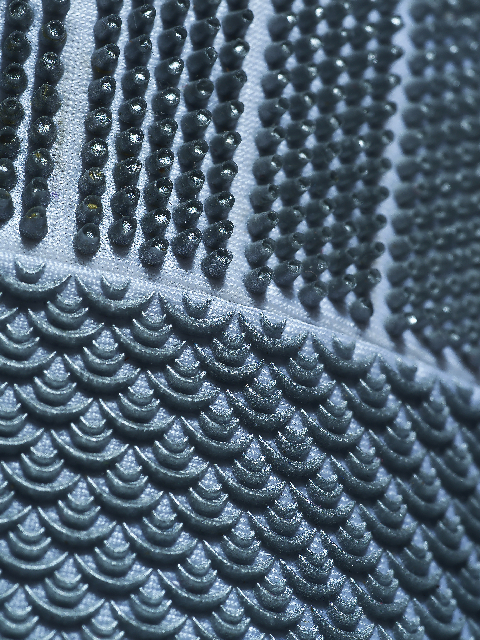

Our revolutionary high-tech process allows us to coat, shape, mold, and print polymers onto textile fabrics with incredible precision, creating 3D micro shapes as small as 20 microns. The design and placement of these micro-structured shapes are meticulously executed using advanced 3D, animation, and CAD Cam physiological programs, ensuring that each microstructure is purposefully driven with mapped physiological characteristics.

During the textile coating process, we carefully consider the individual characteristics of each microstructure, controlling factors such as shore hardness, elasticity, and tensile strength to achieve specific outcomes such as grip and slip control, vibration absorption, shock absorption, ventilation and cooling, conductivity, trip positioning, and wet & dry grip weather. Our attention to detail and focus on purpose-driven design sets our technology apart in the industry.

Our Polymers have the following characteristic capability

· Fireproof

· Nontoxic

· Freeze resistance

· Slowing temperature conductivity (hot and cold)

· Anti-static

· Histamines and phthalate-free

· Flexible and high elastomer memory

· Infra-red nondetectable

· Flash proof

The technology is mostly used in the following fields

· Health, Fire and Rescue

· Tactical combat

· Elite & Olympic sports application

· Work wear